Redefine Precision with SLS

Technology Overview

SLS is a 3D printing technology that uses a laser to sinter powdered materials like Nylon (PA6, PA12), sand(resins with a low phenol content), and PSB thermoplastic powder, into solid structures. The process involves spreading a powder layer, melting it with a laser to form the object, and repeating with successive layers until completion.

Versatility

Durability

Speed

Reliability

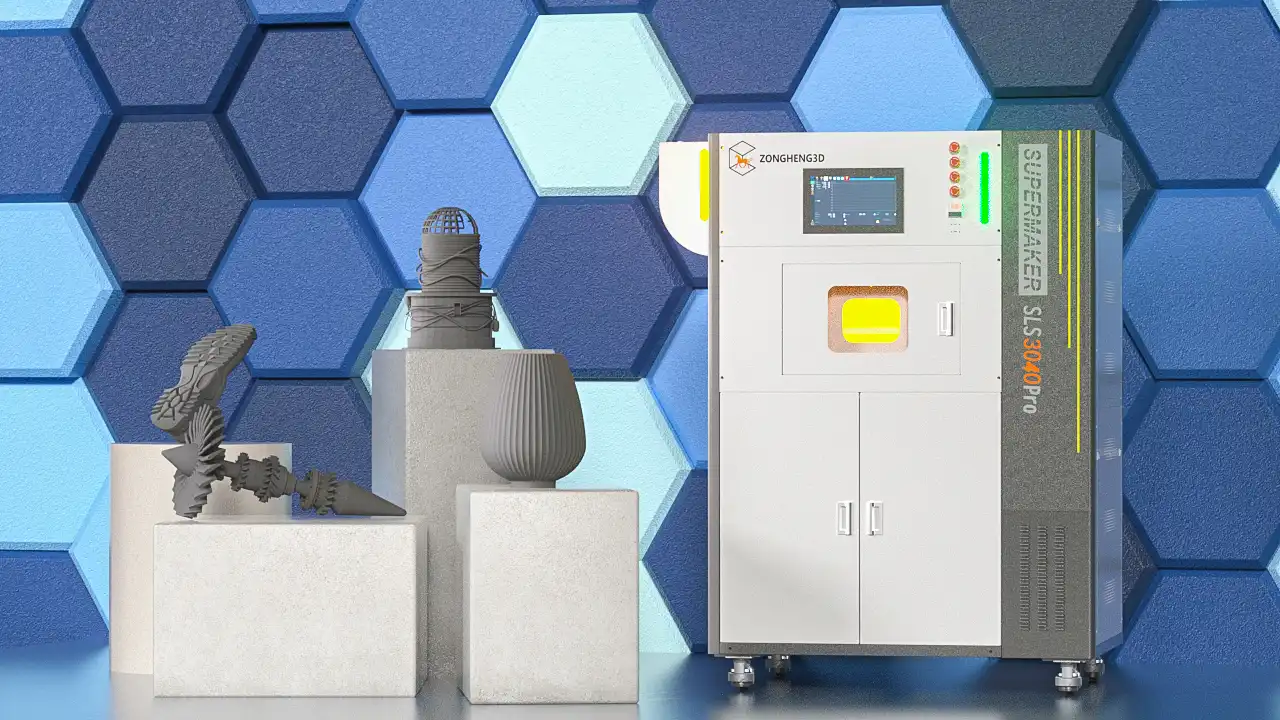

Our Machine

SLS – 3540 Pro

The SLS3540 Pro is an industrial-grade nylon SLS 3D printer designed for rapid, cost-effective production across demanding industries. It stands out with its compact size and material efficiency, while maintaining the same printing accuracy and quality.

- Printing Volume: 350 x 350 x 430 MM

- Materials: PA11,PA12, nylon with glass fiber

- Layer thickness: 0.07~0.3mm

- Maximum scanning speed: 15M/S

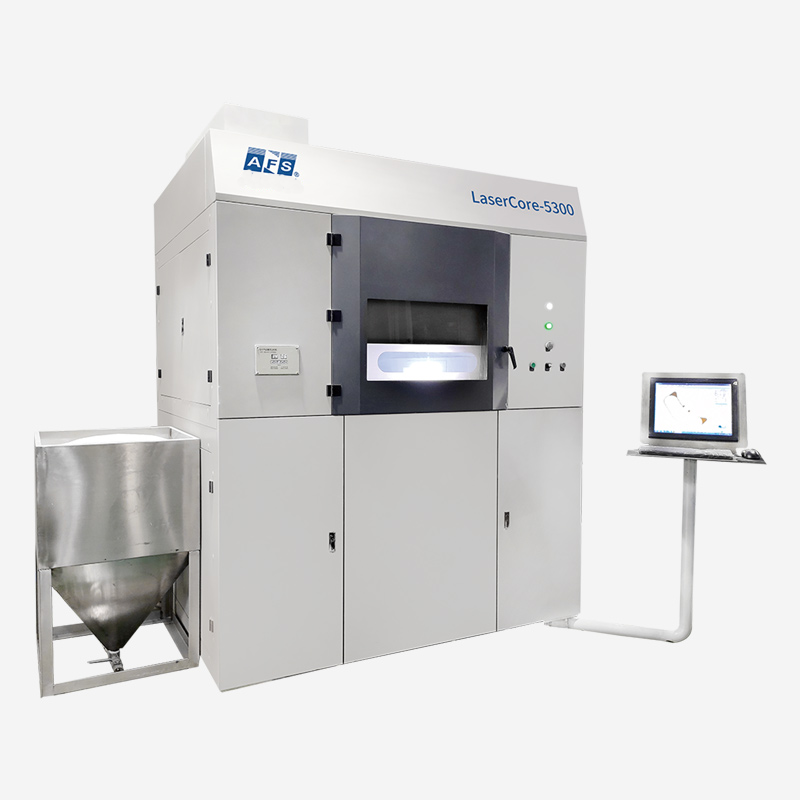

LaserCore – 5300

The industrial SLS 3D printers, LaserCore 5300 and LaserCore 6000, offer high precision and excellent stability, making them suitable for a wide range of applications. They are currently exported to several art casting enterprises and have received positive feedback.

- Print Volume: 700×700×500mm

- Materials: Resin sand/precision casting mold material/engineering plastics

- Layer thickness: 0.08-0.35mm

- Maximum scanning speed: 6m/s

LaserCore – 6000

This machine is specifically designed for SLS sand coating and PSB powder molding. The final products are high in strength and durability, low in thermal expansion, excellent thermal stability and conductivity, and smooth surface finish with intricate geometries.

- Print Volume: 1050×1050×650mm

- Materials: Resin sand/precision casting mold material/engineering plastics

- Layer thickness: 0.08-0.35mm

- Maximum scanning speed: 6m/s

AFS 500

SLS with coated sand and PSB powder creates strong, durable products with smooth finishes and intricate designs. It ensures low gas emissions, thermal expansion, excellent thermal stability, and good mold release. PSB powder adds non-toxic, rigid, and high-impact properties, with low water absorption and easy paintability.

- Print Volume: 500×500×500mm

- Materials: Resin sand/precision casting mold, material/engineering plastics

- Layer thickness: 0.08-0.35mm

- Maximum scanning speed: 6m/s

Why Choose Our Machine?

Advanced Innovation

Stay ahead with the latest advancements in SLS 3D printing.

Reliable Performance

Trusted for consistent and dependable performance

Versatile Compatibility

Seamlessly switch between various materials to suit different applications.

Prompt Support

Receive expert guidance from setup to production.

Case Presentation

Explore our gallery featuring advanced projects created with SLS technology, highlighting the precision, versatility, and innovation of our 3D printing solutions. Transform your industry and discover your application field.

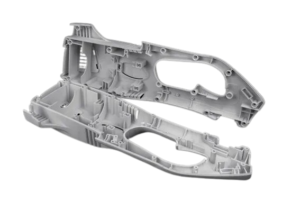

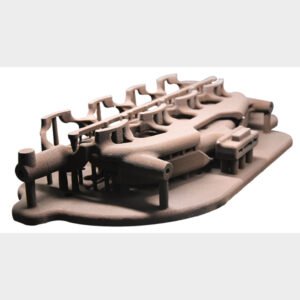

Aerospace

A complex model manufactured with SLS 3d printing for optimal performance revolutionizing aerospace. We accelerate both design and prototyping processes.

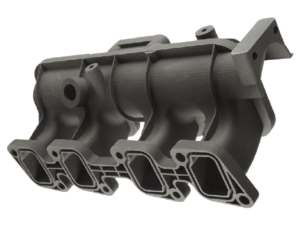

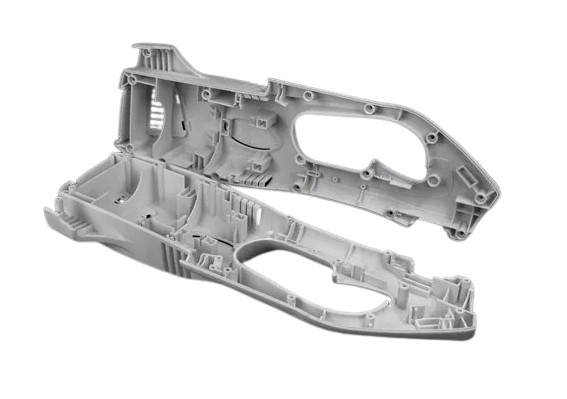

Automotive

This automotive part, crafted with SLS technology, exemplifies cutting-edge design and precision. We provide on-demand and tailored production solutions.

Healthcare

The leg orthosis helps patients with peroneal muscle deficits and gait problems. Our SLS model can customize the fit, including a plantar, while a flexible, parametric ankle joint provides tailored support and control.

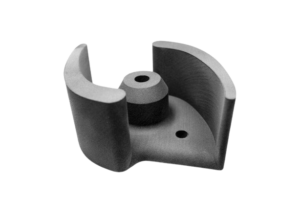

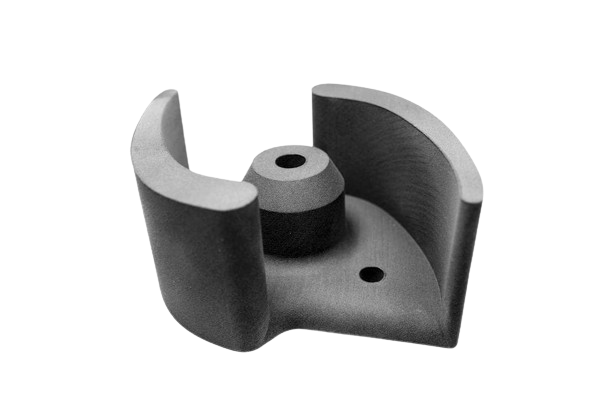

Manufacturing

A 3D printed water pump impeller, created through multiple prototype iterations. SLS technology transforms the prototyping process by

- Speeding up design iterations with functional prototypes ready in hours, not weeks

- Creating complex geometries without tooling costs

- Reducing time-to-market and enhancing competitiveness