Industrial Robotic Arm FDM 3D Printers

Technology Overview

Robotic arm FDM 3D printing utilizes a robotic arm equipped with an extrusion head to deposit thermoplastic materials layer by layer. This technology offers exceptional flexibility in movement, allowing the printer to handle complex geometries, large parts, and various orientations. It supports a range of materials, including high-performance thermoplastics, making it ideal for both industrial applications and detailed prototypes.

Increased Build Size

Enhanced Precision and Detail

Efficient Production Process

Versatile Printing Capabilities

Our Machine

Select the Ideal 3D Printer Model for Your Unique Needs

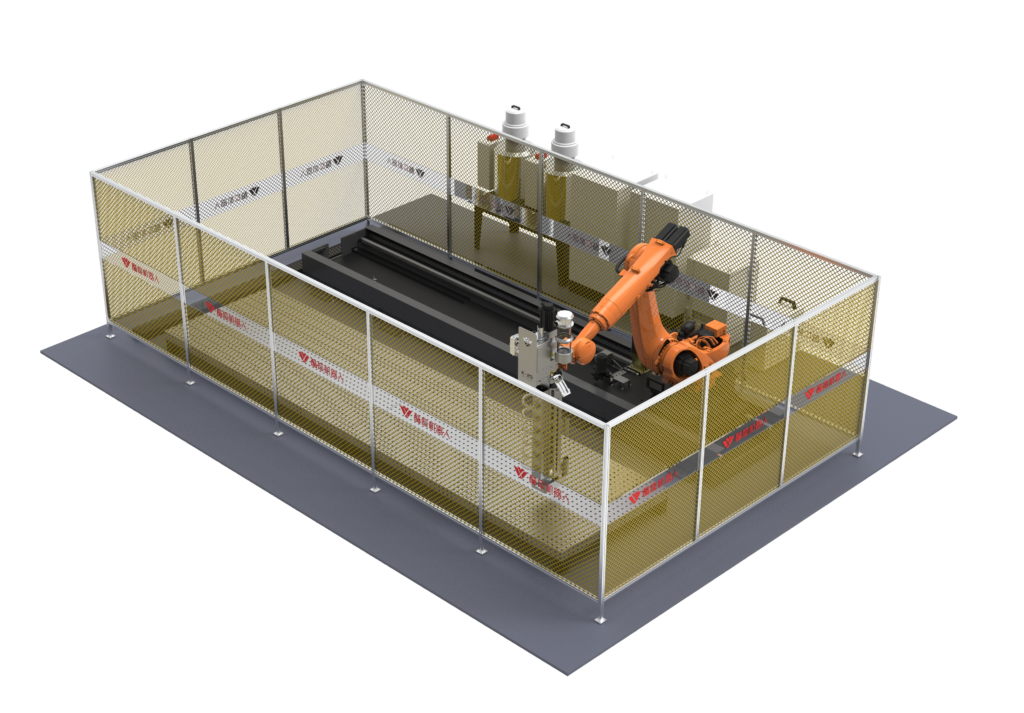

BRAM – P300

- Print head: K20 (20kg/h) or K50 (50kg/h)

- Building Size: 2m x 1 m or 3m x 1m

- 6 Axis robot

BRAM – P300E

- Print head: K20 (20kg/h) or K50 (50kg/h)

- Building Size: 4m x 2 m or 6m x 2m

- 7th Axis robot (adds mobility and flexibility)

Contact us now to get to know more details about our machine!

Why Choose Our Machine?

Advanced Geometric Capabilities

Robotic arms can access and print in multiple orientations

Enhanced Customization

Allows for dynamic adjustments in real-time

Large-Scale Production

The extended reach and movement flexibility of robotic arms can print large scale products

Reduced Material Waste

The precision of robotic arms helps in minimizing material waste through efficient deposition

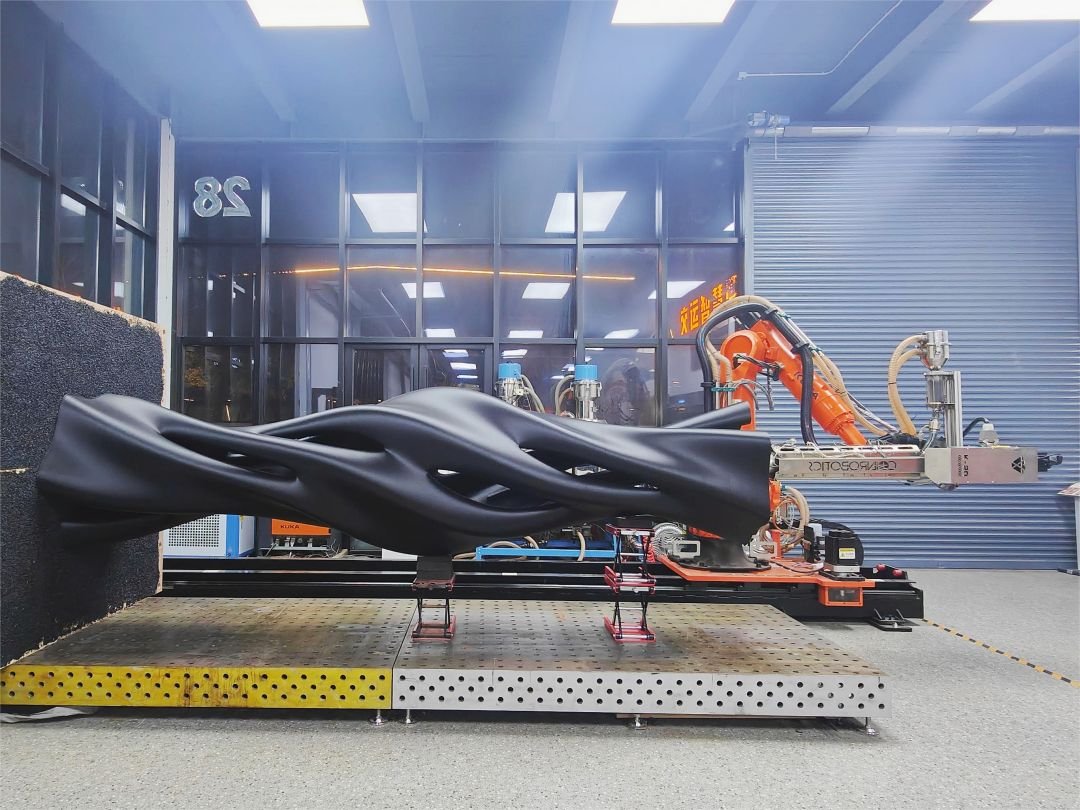

Case Presentation

Discover our cutting-edge 3D printing capabilities through our gallery. From a bridge printed in 19 hours to a transparent chair table set, explore how our horizontal and retraction printing technologies create large-scale and intricate designs in one piece.

Bridge

The complex structure with curved surfaces and hollow sections, is printed in one piece using our machine in 19 hours.

Chair Table Set

The fully transparent chair table set blend seamlessly with the scenic waterside surroundings.

Architecture/ Art

Horizontal printing technology enables the one-piece formation of large-scale components, while retraction printing technology allows for the creation of hollow and perforated designs.