Forge the Future with SLM Metal

Technology Overview

SLM stands for Selective Laser Melting. It is a type of 3D printing technology that uses a laser to selectively melt powdered material (usually metal) into a solid structure. The process is similar to SLS printing, but instead of sintering the powder, it melts it completely .

Efficiency

Innovation

Sustainability

Precision

Our Machine

Select the Ideal 3D Printer Model for Your Unique Needs

M140C

- Print Size: diameter 140mm, height 100mm

- Number of Laser: 1

- Scanning speed: 0~10m/s

M180D

- Print Size: diameter 180mm, height 100mm

- Number of Laser: 2

- Scanning speed: 0~7m/s

m220

- Print Size: 140 x 220 x 100/200 mm

- Number of Laser: 2

- Scanning speed: 0~10m/s

M300

- Print Size: 300 x 300 x 400mm

- Number of Laser: 2

- Scanning speed: 0~10m/s

M420Q

- Print Size: 420 x 380 x 300mm

- Number of Laser: 4, 6 and 8 lasers are optional

- Scanning speed: 0~10m/s

M500

- Print Size: 300 x 500 x 400mm

- Number of Laser: 2, 3 and 4 lasers are optional

- Scanning speed: 0~10m/s

M800

- Print Size: 650 x 650 x 800mm

- Number of Laser: 4, 6 and 8 lasers are optional

- Scanning speed: 0~10m/s

M120

- Horizontal/vertical gradient function available

- Print Size: diameter 140mm, height 100mm

- Max Scanning Speed: 6m/s

- Max Molding Accuracy: ±0.1mm

- Max Printing Efficiency: 20cm3/h

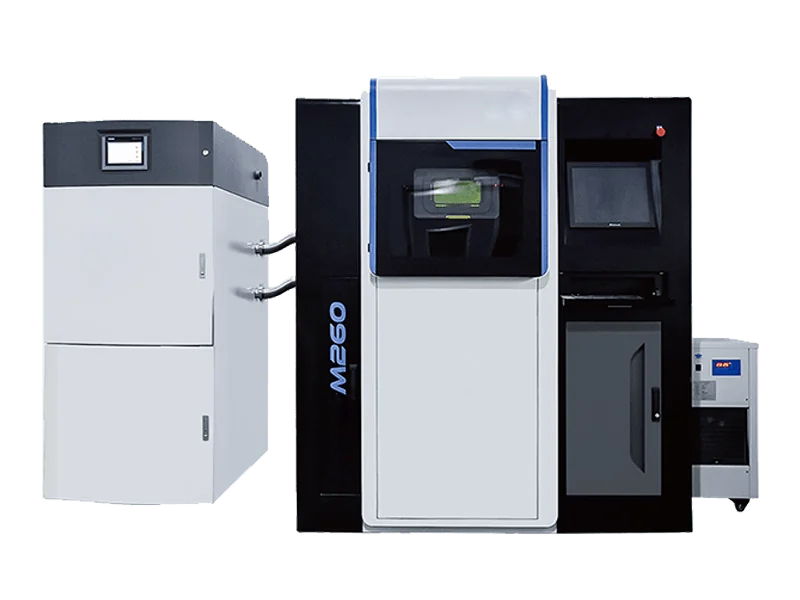

M260

- Print Size: 260 × 260 × 320 mm

- Max Scanning Speed: 6m/s

- Max Molding Accuracy: ±0.1mm

- Max Printing Efficiency: 20cm3/h

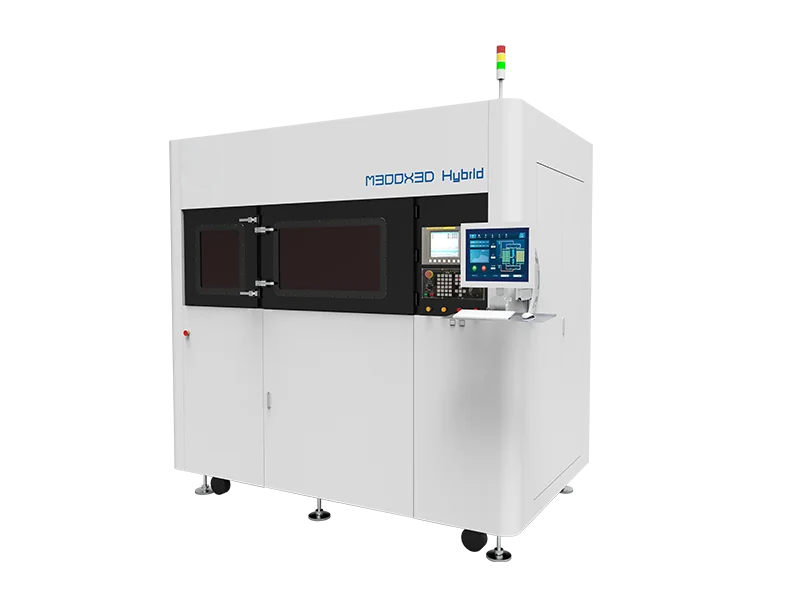

m300xas

- Horizontal/vertical gradient printing

- Print Size: 300 × 300 × 250mm

- Max Scanning Speed: 6m/s

- Max Molding Accuracy: ±0.1mm

- Max Printing Efficiency: 50cm3/h

Contact us now to get to know more details about our machine!

Why Choose Our Machine?

High Precision and Accuracy

Delivers detailed parts with exceptional dimensional accuracy.

Customizable Laser Options

Flexible laser power settings for diverse needs.

Versatile Material Compatibility

Works with a wide range of metals including stainless steel and titanium.

Comprehensive Support and Software

Includes advanced processing and control tools for efficient operation.

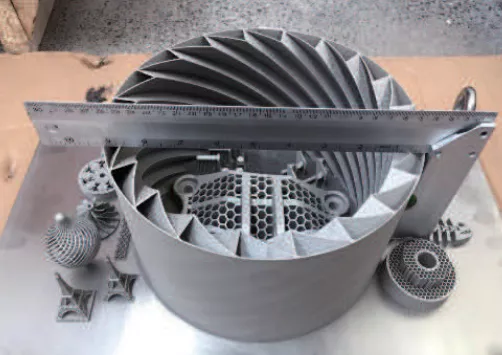

Case Presentation

Check out our gallery showcasing cutting-edge projects brought to life with SLM technology, demonstrating the precision, versatility, and innovation of our metal 3D printing solutions.

Aerospace

Art/ Display