DED: Precision and Power for Metal Manufacturing

Technology Overview

DED is a metal 3D printing process that uses an energy source, such as a laser or electron beam, to melt and fuse metallic powder or wire feedstock. The process is used to create large metal parts with high deposition rates and relatively low resolution. DED is capable of working with various metals and alloys, making it ideal for industries like aerospace, automotive, and defense.

Repair and Reuse Capabilities

Enhanced Material Performance

Flexibility in Material Application

Reduced Processing Time and Costs

Our Machine

Select the Ideal 3D Printer Model for Your Unique Needs

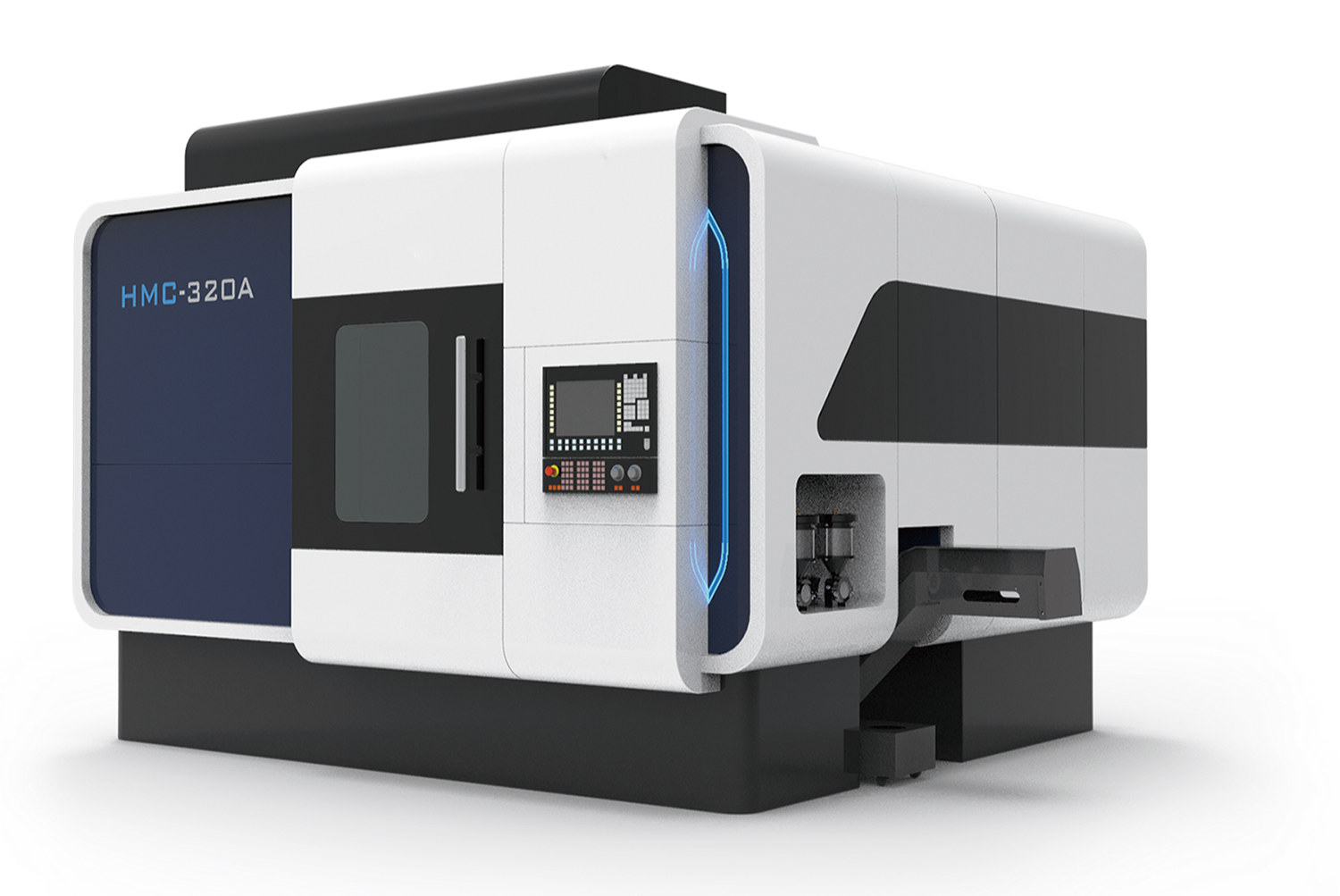

HMC Collection

Our HMC collection is a hybrid manufacturing centre with five-axis, high efficiency and high precision. It’s especially suitble for the manufacturing and remanufacturing of complex precision products, such as turbine blades, molds, etc.

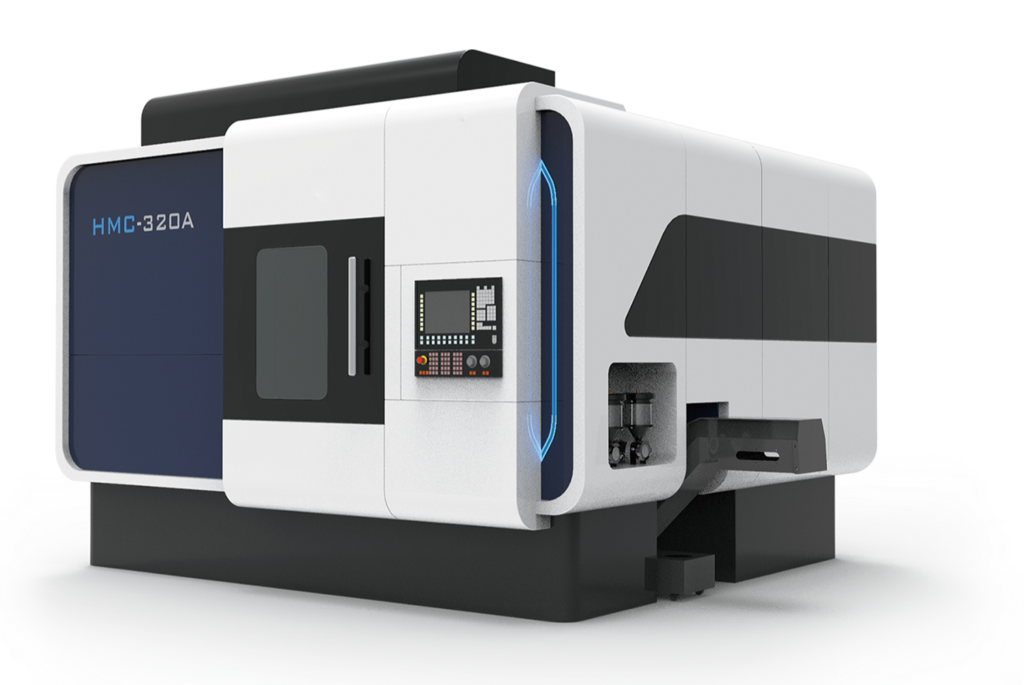

HMC – 320A

- Processing Diameter: Ø320mm

- Three-Axis Travel: 600/320/320mm

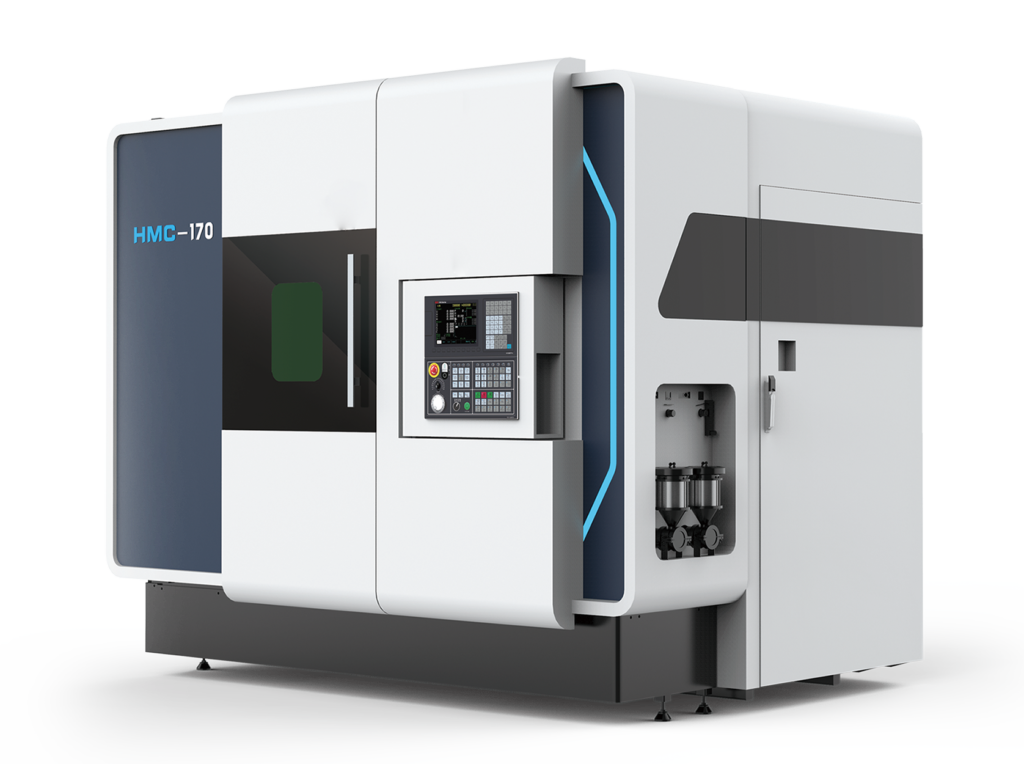

HMC – 170A

- Processing Diameter: Ø170mm

- Three-Axis Travel: 400/200/300mm

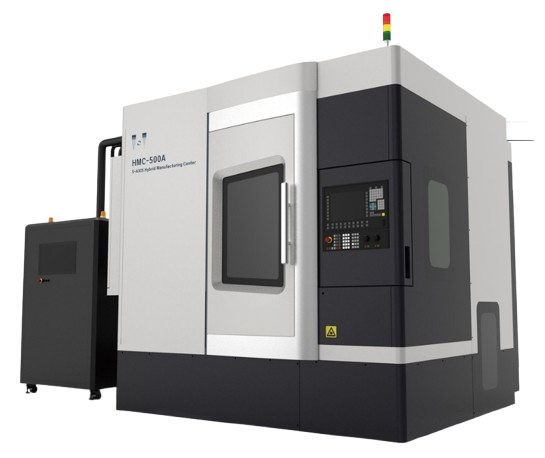

HMC – 500A

- Processing Space: Ø500mm x H450mm

- Surface accuracy up to 1.6µm

LAM Collection

Our LAM collection adopts controlled atmosphere with Ar recycling system to achieve a low O2 level (<20ppm). It’s based on coaxial wire feeding mechanism. It’s widely used in for R&D, new material development, repairing of small titanium alloy parts and manufacturing of all sized components.

LAM – 260S

- Motion Mode: three-axis, four-axis, five-axis

- Processing Space: 260 x 260 x 260 mm

- Laser Power: 1000W – 2000W

LAM – 400S

- Motion Mode: three-axis, four-axis, five-axis

- Processing Space: 400 x 400 x 400 mm

- Laser Power: 2000W – 3000W

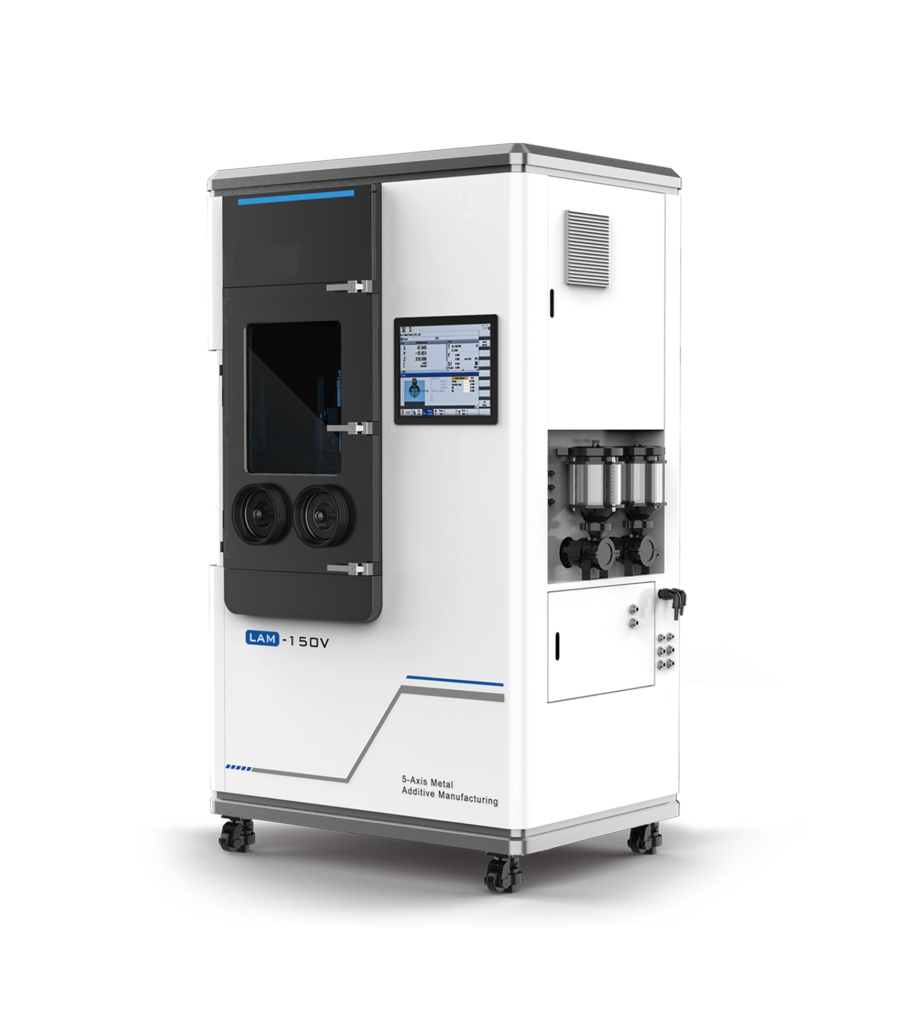

LAM – 150V

- Motion Mode: simultaneous 5-axis

- Processing space: 200 x 150 x 160mm

- Laser Power: 500W – 1000W

LAm – 1008S

- Motion Mode: simultaneous 5-axis

- Processing Space: 1000 x 800 x 900mm

- Laser Power: 3000W – 6000W

LAM – 2015S

- Motion Mode: simultaneous 5-axis

- Processing Space: 2000 x 1500 x 2500mm

- Laser Power: 3000W – 8000W

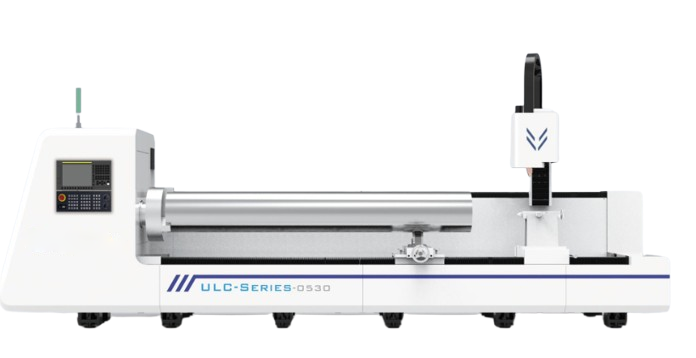

ULC Collection

Our ULC (ultra-high-speed laser cladding) collection requires small heat input to the workpiece and the products has much smoother surface than traditional laser cladding. The coating thickness can also be adjusted accordingly. In special cases, multi-cladding can also be used.

ULC – 0530

- Maximum Workpiece Diameter: Ø500mm

- Maximum Length: 3000mm

- Cladding Efficiency: 1m2/h

Powder Utilization: 85%

ULC – 1240

- Maximum Workpiece Diameter: Ø1200mm

- Maximum Length: 2000mm

- Cladding Efficiency: 0.8m2/h

- Powder Utilization: 85%

ULC 0630

- Maximum Workpiece Diameter: Ø630mm

- Maximum Length: 3000mm

- Cladding Efficiency: 1m2/h

- Powder Utilization: 90%

We also have this model in enclosed version and integrated outer/inner wall version.

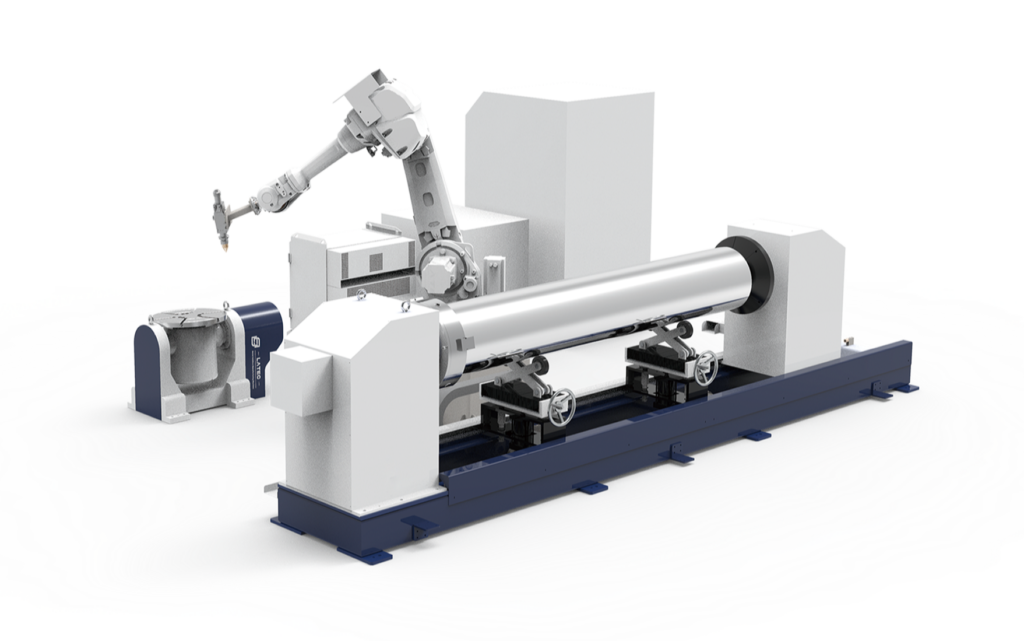

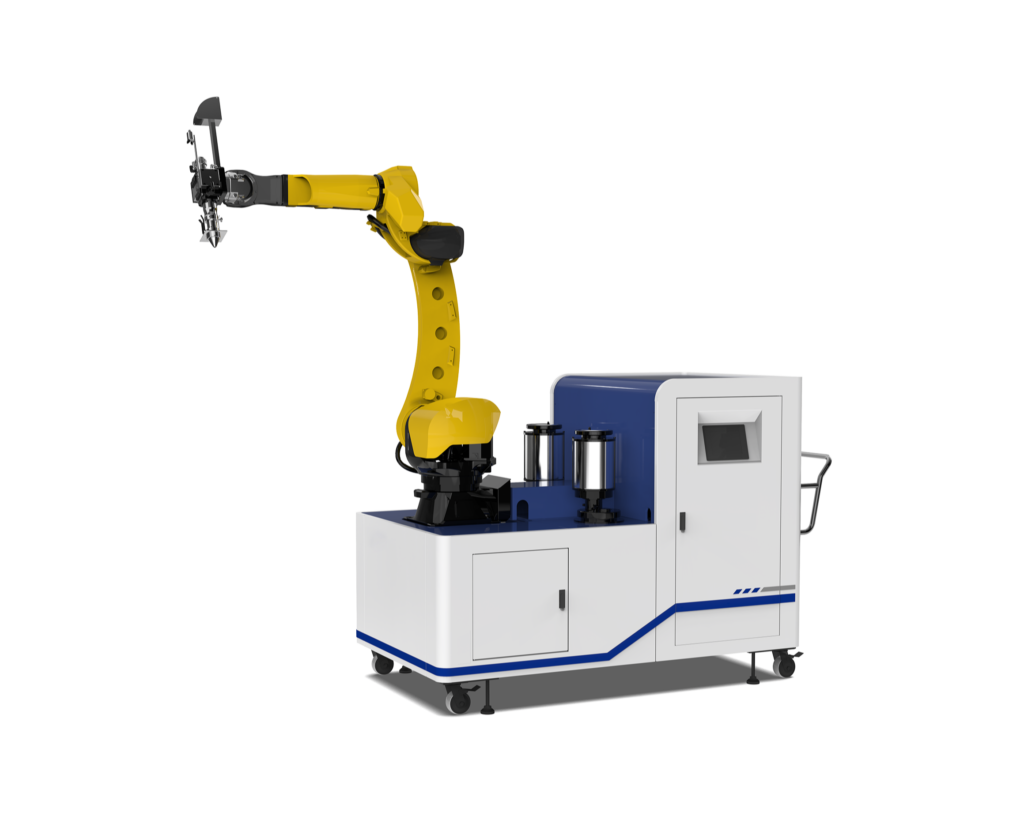

Robot Collection

LOM 3000

It’s suitable for various working environment and has a wide range of applications. It can be used for manufacturing of cylindrical components and components with curved surfaces.

- Motion Mode: six degree robot with additional axis

- Robot Arm: 1500-3000mm optional

- Number of Powder Feeders: 2

- Remote Control

MRL

It’s designed for the on-site repair of large-scale equipment, where disassembly and transportation are not feasible.

- Motion Mode: six degree robot with additional axis

- Robot Arm: 1400-2000mm

- Number of Powder Feeders: 2

Contact us now to get to know more details about our machine!

Why Choose Our Machine?

High Integration and Stability

Ensuring reliable and consistent performance.

Mature Technology

Minimizing operational risks and ensuring effective results.

Smooth and Defect-Free Cladding

Reducing the need for extensive post-processing

Minimal Thermal Deformation

Preserving the structural integrity of the material.

Case Presentation

Explore our gallery, where we showcase industrial applications using our advanced machine. Explore how our machine revolutionizes manufacturing and repair across industries, offering both restoration and performance enhancement to extend the life of critical components. Each example highlights the precision, efficiency, and versatility of our technology.

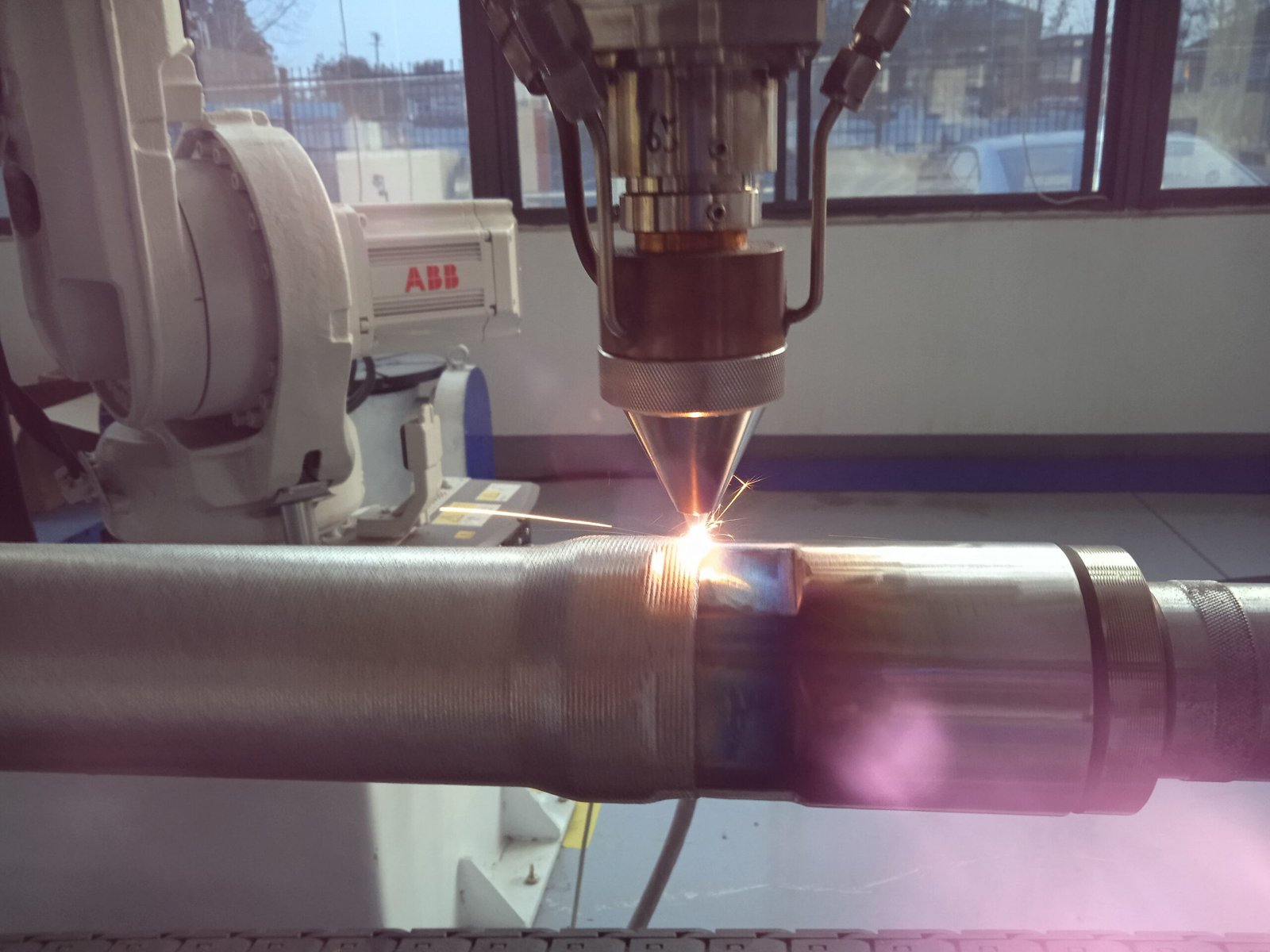

Oil Well Pipe Repair

Our machine restores oil pipes affected by stress corrosion cracking, repairing damage and enhancing material performance to withstand the harsh conditions of oil well production.

Turbine Blade Restoration

See how turbine blades, critical to engine performance, are repaired and reinforced using our machine, allowing them to endure extreme high-temperature and high-pressure environments while extending their operational lifespan.

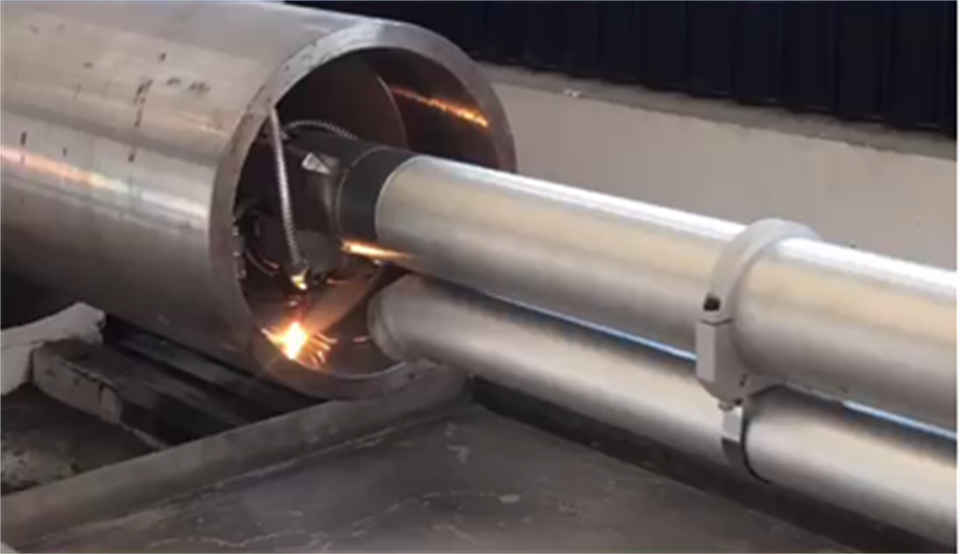

Hydraulic Support Column Coating

Explore the process of applying corrosion-resistant coatings to the inner surfaces of hydraulic support columns, showcasing how our machine offers a superior alternative to traditional methods, with reduced heat input and cost.