Ceramic 3D printing with Binder Jetting

Technology Overview

Ceramic 3D printing with Binder Jetting technology deposits a liquid binder onto layers of ceramic powder, building parts layer by layer. After printing, the part undergoes bisque firing and glazing to solidify and finish the model. This method allows for the creation of complex, precise ceramic structures, making it suitable for applications in art, education, biomedical, and advanced manufacturing.

Patented Technology

Versatile Applications

Customizable Options

Post-Processing Integration

Our Machine

Select the Ideal 3D Printer Model for Your Unique Needs

ComeTrue-M10

Specially designed for ceramic crafts and education using custom ceramic composite powders and post-process ceramic firing. It has a shrinkage ratio of 16-17% after bisque firing, with no further shrinkage after glaze firing. It is also widely used for inkjet-based advanced manufacturing in fields like industrial ceramics, biomedical bone ceramics and polymers.

- Printing Volume: 200x160x150mm

- Maximum vertical build speed: 20mm/hour

- Resolution: 1200 x 556 dpi

- Type: Desktop

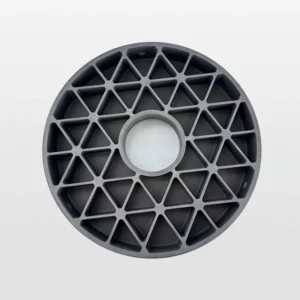

3DPTEK-J400P

This production-oriented equipment is designed for MIM, mold, tooling, and other industries. It features a top-feeding powder single-cylinder structure, V+ precise powder drop system, dual-roller high-density powder spreading, automatic nozzle cleaning, and a built-in air purification system for easy, efficient operation.

- Print Volume: 400×400×300mm

- Highest Resolution: 1200 dpi

- Maximum Printing Accuracy: ±0.1mm

- Maximum Molding Efficiency: 3.6L/h

3DPTEK-J800P

With flexible powder and binder ink replacement, it offers up to ±0.1mm printing accuracy, 1200 DPI resolution, 10L/h printing speed, and 67% green blank density. We also independently design binder formulations to support custom material development for new applications.

- Printing Volume: 800×500×400 mm

- Highest Resolution: 1200 dpi

- Maximum Printing Accuracy: ±0.1mm

- Maximum Molding Efficiency: 10L/h

Contact us now to get to know more details about our machine!

Why Choose Our Machine?

Patented Technology

Built with patented technology for advanced ceramic 3D printing

Versatile Applications

Supports custom ceramic powders for crafts, education, industrial components, and biomedical applications

Customizable Options

Flexible Z-axis layer thickness and adjustable parameters for tailored results in research and development

Post-Processing Integration

Includes ceramic firing post-process, with controlled shrinkage for accurate final dimensions after bisque firing and glaze firing

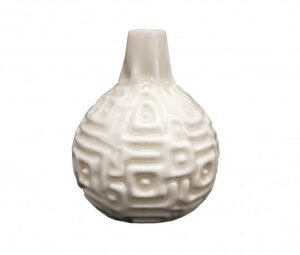

Case Presentation

Explore our gallery of ceramic printed products, showcasing its versatility in ceramic crafts, education, and advanced manufacturing research. Perfect for both creative and industrial applications.

Architecture

Ceramic printing helps preserve cultural heritage by digitizing historical relics using 3D scanning for archiving and repair simulations. They also enable artists to blend technology and art, showcasing unique aesthetics in their designs.

Bio-Medical and Health Care

In biology and healthcare, emerging applications include 3D fetal imaging, virtual plastic surgery models, human organ displays, lecture models, and medical instrument mold manufacturing. These products are widely used for education and surgical planning.

Art & Industrial Design

In industrial and manufacturing design, our printers shorten design modification time. By creating samples before molding, it reduces errors and mold modification costs. Unlike traditional CNC, it builds parts layer by layer, making complex models easier to produce.