High-performance Pellet 3D printing

Technology Overview

Pellet FDM 3D printing is an additive manufacturing process that uses thermoplastic pellets as the raw material instead of the typical filament. In this process, plastic granulates are melted and extruded layer by layer to build up a 3D object. This technology is particularly advantageous for large-scale production, as it offers faster printing speeds and lower material costs compared to traditional filament-based FDM printing.

Affordable Material Costs

Scalability

Material Flexibility

Eco-Friendly

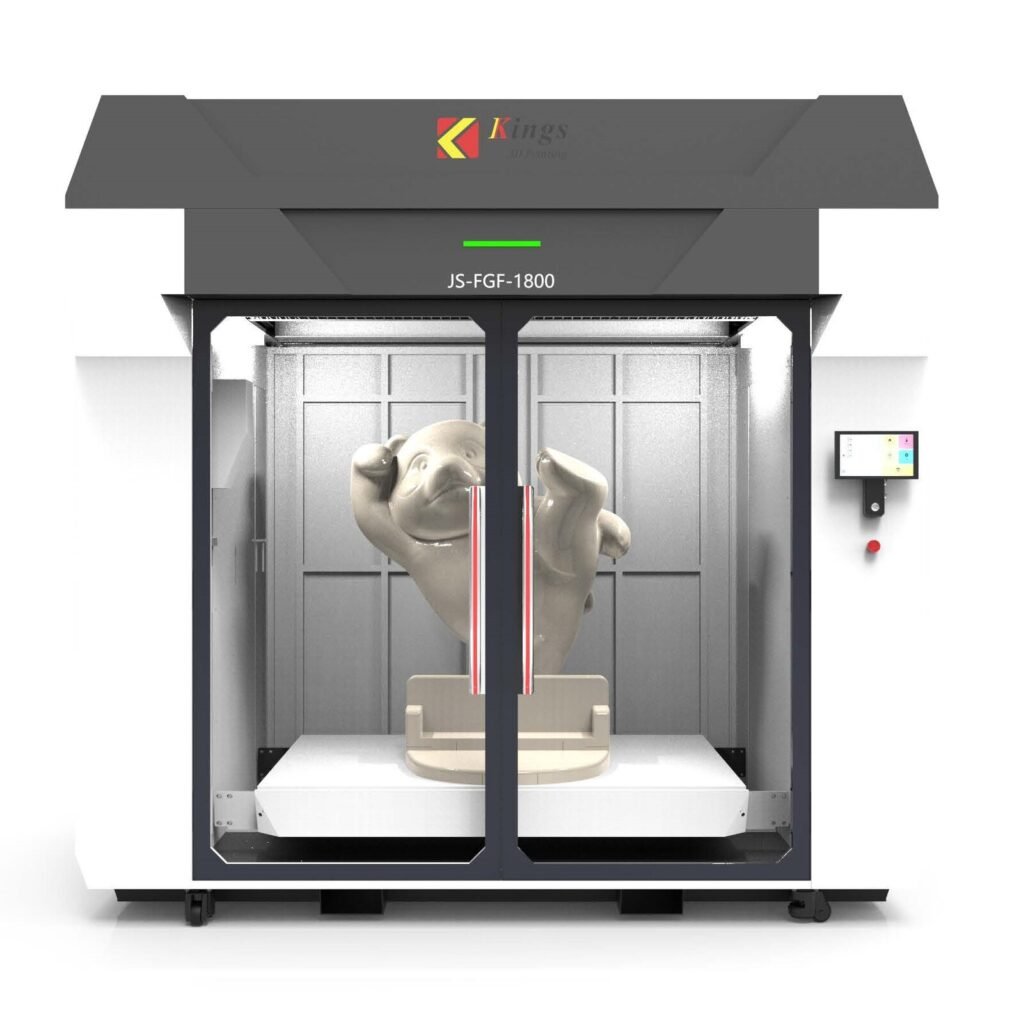

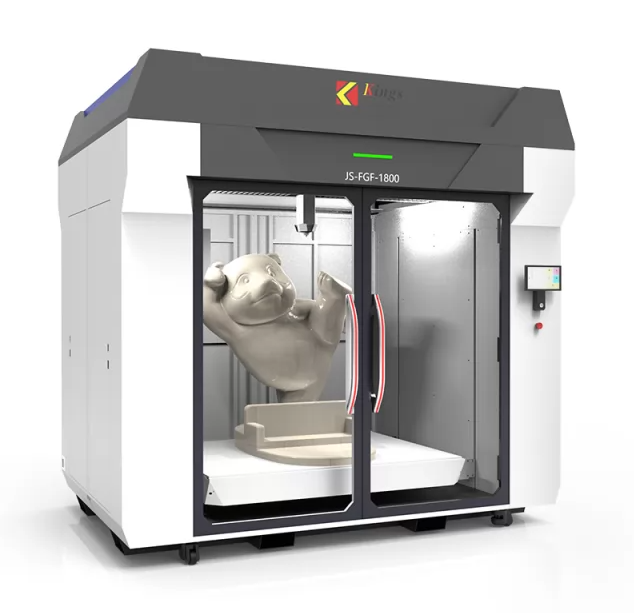

Our machine

FGF – 1800

Printing Volume

1800 x 1300 x 1300 MM

Optional Functions

oblique printing, vertical printing function

Optional Nozzle Diameter

1-8mm

Materials

PLA/PETC/ABS/PC/PA/PP/HDPE/TPU/TPV/EVA/PETG+GF/PPS+GF/

PA+CF/ABS+CF/PC+CF/PEI+CF etc.

Automatic feeder

Integrated

Slicing supported formats

STL/OBJ/AMF/3MF

Contact us now to get to know more details about our machine!

Why Choose Our Machine?

Cost-Effective

Use low-cost granular and polymer composite materials

Large Build Size

massive build area, ideal for furniture and sculptures

High Performance

Fast printing speeds and high-strength parts with outdoor weather resistance

Versatile Materials

Choose from cost-effective ABS and PETG to high-performance PPS and carbon fiber composites

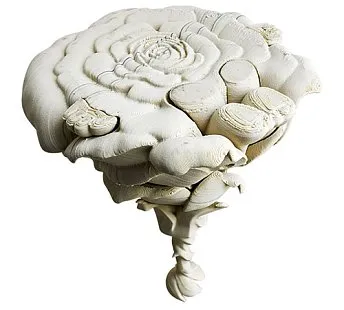

Case Presentation

Explore our gallery featuring advanced projects created with pellet FDM technology. It is widely used for furniture designing, mining industry, oil & gas industry, toy industry, art crafts, mold manufacturing, plaques, landscape signs etc.

Display

Art crafts

Furniture

Swan stool

Display

Vase