Learn more about this technology →

Affordable Precision: FDM 3D Printing for Fast, Versatile Solutions.

Technology Overview

Fused Deposition Modeling (FDM) is a widely used additive manufacturing technology where thermoplastic materials are melted and extruded through a heated nozzle to build up parts layer by layer. The process begins with a 3D model that is sliced into thin cross-sections using specialized software. The printer then deposits the material layer by layer according to these cross-sections, allowing for the creation of complex geometries and functional parts.

Cost-Effective

Versatile Material Options

Ease of Use

Rapid Prototyping and Production

We also sell pellet extruder separately,

contact us now!

FDM Categories

Choosing the Right Technology and the Right Model

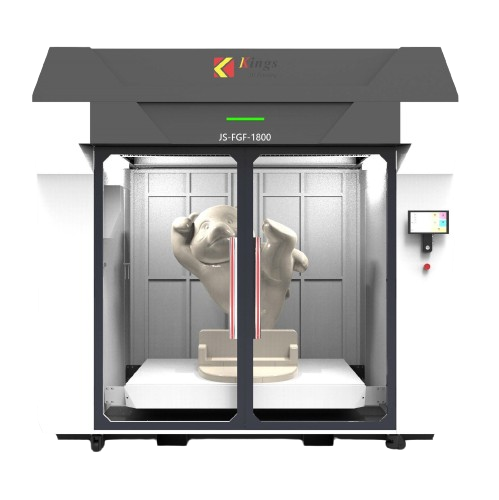

Pellet FDM 3D printing uses thermoplastic granules for faster, cost-effective production, ideal for industries like automotive and construction.

High Temperature FDM

High-temperature FDM 3D printing uses elevated temperatures to create durable, heat-resistant parts from advanced thermoplastic materials.

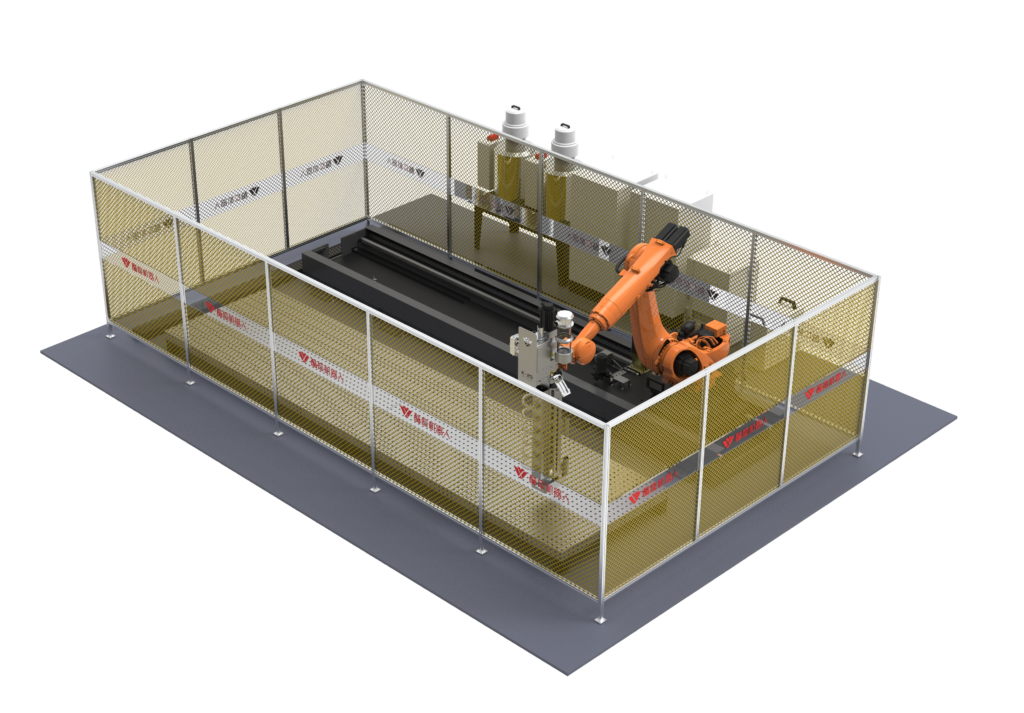

Robotic Arm FDM

Robotic arm FDM 3D printing combines large-scale capabilities with exceptional flexibility and mobility to create complex, precise designs with ease

Large-scale FDM 3D printing enables the creation of large, intricate parts with high precision and efficiency, using bulk thermoplastics for cost-effective and customizable production.